Armour College of Engineering Researchers Publish New Synthesis Technique for Developing Nanostructured Materials in Scientific Reports

Researchers at Illinois Tech recently unveiled a major breakthrough in nanotechnology processing that reduces the time, and increases the amount of product that can be manufactured on an industrial scale. The new technique makes nanotechnology economically viable for numerous applications, including pollution control for vehicles, reduction in waste heat from vehicles and electronics, and removal of toxic waste from water.

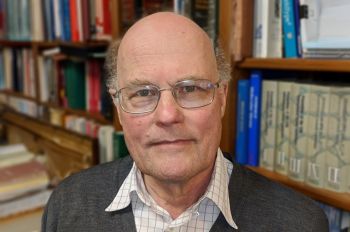

“This novel approach is capable of producing nanostructured material on an industrial scale and on an economically viable time-scale thus overcoming two major hurdles in nanotechnology; inability to scale up to industrial production quantities and economically unacceptable synthesis times,” says Philip Nash, Charles and Lee Finkl Professor of Metallurgical and Materials Engineering.

Nash, working with graduate students Yang Zhou and Tian Liu of Armour College of Engineering’s Department of Mechanical, Materials, and Aerospace Engineering, detailed his findings in a paper he co-authored with colleagues from Tianjin University, China on the large-scale synthesis of nanostructured plates.

The paper, published in Scientific Reports, and titled, “The Large Scale Synthesis of Aligned Plate Nanostructures,” describes a paradigm-shifting synthesis technique that can be applied to many alloy systems to produce functional material for applications in energy technology, catalysis, and waste-water treatment. The technique involves developing nanoscale two-phase microstructures through discontinuous precipitation followed by selective etching to remove one of the phases. The method may be applied to any alloy system in which the discontinuous precipitation transformation goes to completion.

The Ni-Co-Al alloy discussed in the paper epitomizes the concept. The material is ductile before heat treatment so that it can be fabricated into complex shapes, including tubes and wire. The alloy can then be treated to produce the nanostructure either on the inside, outside, or both sides of the tube. The tube will retain its structural integrity and has the added functionality of the nanoscale surface.

View or download the paper here.